We were ferried in a shuttle bus to the Logistics Wing's headquarter building where we were delivered a presentation by Major Schufin. The presentation showed us an overview of the air force's organisational structure, the types of aircrafts the air force owns, the types of operations the aircrafts are used for, the lifecycle of the aircrafts before they go into maintenance and such.

Major Schufin giving the presentation

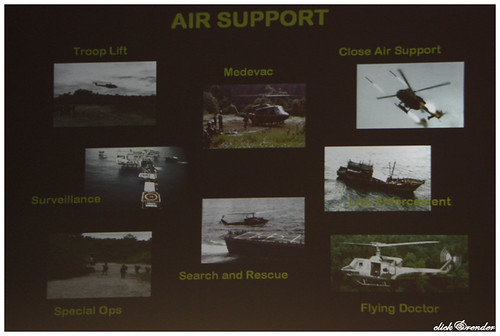

Types of air support provided by the air force

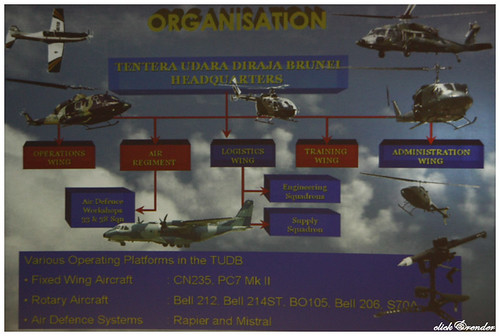

The structure of the organisation

Types of aircraft being maintained by different engineering squadron under the logistics wing. If I remember correctly, the Bell 212 is 30 years old. And, Bell 214ST is 11 years old and is special because its production was in Iran during the time of the Shah in 1970s. The production was completed in the 1990s. It is no longer in production. Excluding Iraq owned 214ST, Brunei owns one of the remaining 39 in the world.

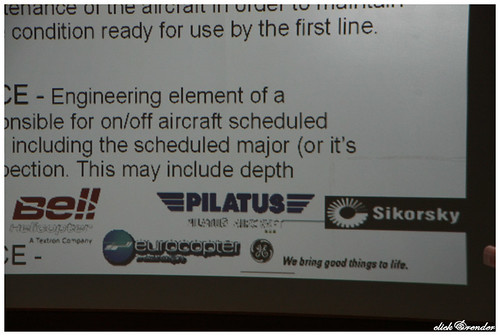

Manufacturers of aircrafts

Helicopter Bell 212 deemed unservicable after 3000 hours of service

Visitors from IET

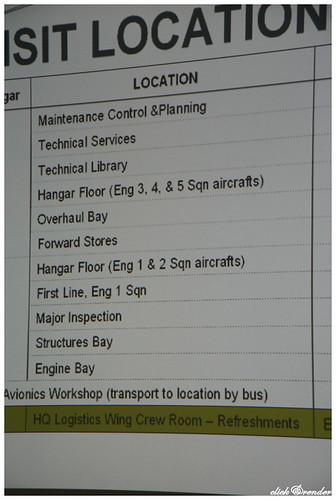

The programme for our visit

The Maintenance Control and Planning unit oversees to every single maintenance work which the aircraft parts undergo and records these details in a maintenance computer system and in log books.

Here is a copy of a log book detailing maintenance work conducted on the engines of aircrafts

Next is the Technical Services unit which oversees to operations pertaining to the aircraft manufacturers, order of parts, etc. Basically, they communicate with relevant parties outside the air force with regards to logistics.

This is the Technical library where master copies of aircraft maintenance manuals and sometimes, flight manuals are kept. They are also in-charge of keeping updated copies of these manuals if published by the aircraft manufacturers. The technical team themselves have lab copies on which they may refer to at the site of maintenance.

Overhaul Bay where the helicopter parts such as the transmitters, valves, joints, shafts and rotor hubs with all the nuts and bolts and other metal parts are inspected and repaired.

Board of tools

I think this is a main rotor hub

To check for damages such as cracks, the metal parts are placed in fluorescent or visible penetrants and checked under ultraviolet light for cracks, leaks and surface discontinuities. This is called dye penetration inspection. These penetrants can be either post emulsifiable or water washable.

Dryer for the parts

Non-destructive testing using magnetic particle, which can come in aerosol, ink or powder

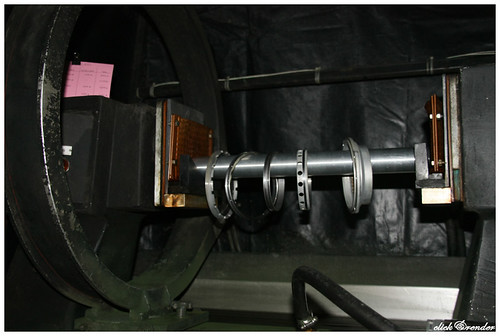

Magnetic field testing

This is a transmission which joins the rotor which holds the blades to the engine using shafts. The disk on the bottom left controls the tilt.

A Pilatus parked in the hanger

Black Hawk being disassembled

Pilatus under maintenance

Logs and Tool Store

A Black Hawk just being towed in

IET visitors viewing the Bell 212

Rear view mirror

Comfy seats?

Winch used for conducting rescue operations for instance

Check out the engine (looking like two short horns) and shaft connecting to the tail rotor

Tail rotor consisting of the hub and the blades

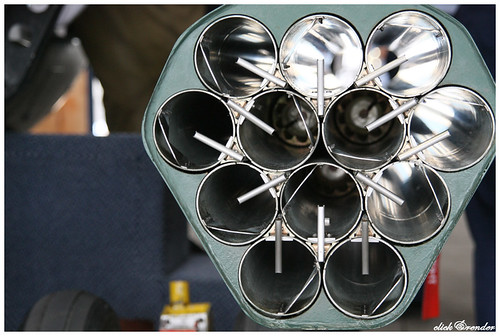

This is the BO 105 with rocket launchers! Except, these rockets are fake.

Flight controls

On the other end of the launcher

A visitor ready to take flight?

BO 105 taken apart

A technical staff working on BO 105

Gas pedal?! I was wrong. It's called a rudder for controlling the tilt.

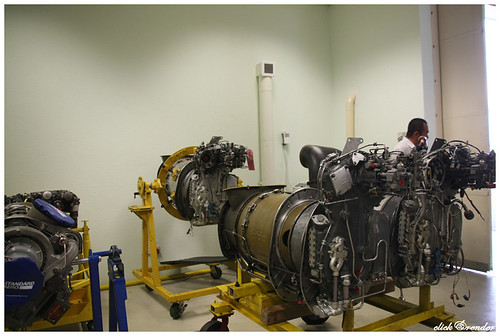

Here we have the Engine Bay. The engine in front is a twin engine unlike the others.

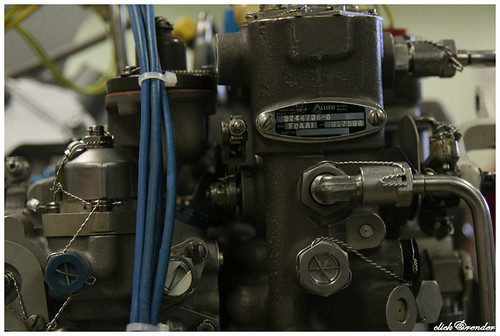

Does this look somewhat familiar to you? Check one of the Bell 212 photos. There are a network of air valves going to different sections of the engine, where at some point, it's compressed or mixed with the fuel.

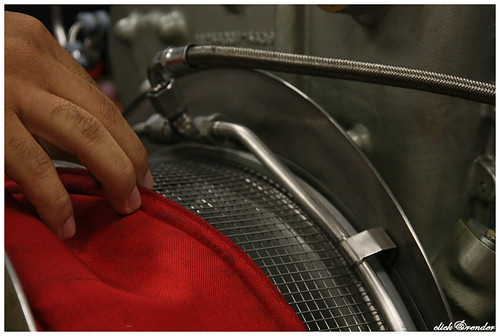

Section of the engine has to be covered to prevent dust from getting in

Another black hawk undergoing maintenance

After our refreshment, representatives from IET Brunei and RBAF exchanged gifts.

CN 235

Everyone waiting for an official photo to be taken

Tada! Everyone with the CN 235

The good news for everyone is that the Royal Brunei Air Force will be opening its doors to the public for RBAF's birthday on the 31st of May 2009.

No comments:

Post a Comment