The visit was definitely interesting for me though I have no engineering background unlike the other members. After all the expected members have arrived, we got ourselves registered at the guardhouse by the gate of the plant. Visitors with camera are to also register their equipment by filling in another sheet.

We were then brought to the main control building where we heard a safety presentation as well as a presentation on the operations of the plant, including Total's operations within our region. After the presentation, safety gears were distributed. These included overalls, safety boots, gloves, protective eyewear, safety helmets and ear plugs. Those bringing cameras are to wear a gas detector so that on detection of gas, one should stop taking photos for fear the gas leak may cause an explosion spurred by the click of the photographic device.

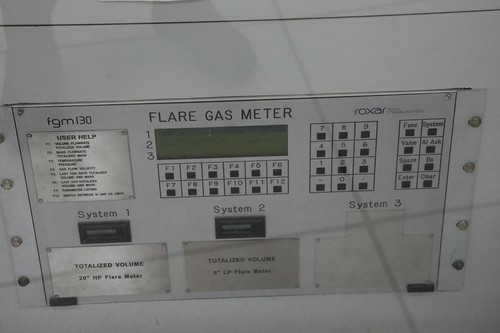

We were guided to the control room where staff members were on close monitor of the readings taken from site sensors and meters. They measure all sorts of parameters; pressure, temperature, flow, density and so forth. The status and readings of the valves, chambers and pipes are all monitored from a separate computer. This particular system looks similar to the one I saw at a visit to the Public Water Works, which used Geographic Information System (GIS). There were other panels with buttons and screens, all for the purpose of control and monitor.

Next, we visited the plant. The general process goes like this:

The oil would arrive and be fed into the slugcatcher. Here, the liquids and the gas are separated. Because the slugcatcher is made up of a series of inclined pipes, the liquids will flow downwards while the gas being lighter will flow upwards. Solid residues will be left in these inclined pipes.

The liquids are processed to separate and stabilise the condensate and water. These are then delivered to the Seria Crude Oil Terminal (SCOT). The gas are processed to remove mercury and CO2 before they are delivered to Brunei Liquefied Natural Gas Sdn Bhd (BLNG).

The plant looks new but from its proudly displayed safety achievement plaque, it has been running for ten years. IET engineer members were applauding Total's effort for keeping the plant well-maintained. The reservoirs and chambers showed no sign of corrosion and everything looked well-kept.

The last time I learned so much on oil and gas was back in my junior high school years during my geography lessons. Having paid such a visit where I get to see the real thing and listen to the experts, this is extraordinary for me.

Reports on this visit can be found here, here and here

IET members listening to the presentation

More IET members on the other side of the room

All the boot were huge! Roch, the plant's HSE supervisor, got me size 6 boots for my size 3 feet.

Everyone putting on the safety attire

Staff member explaining the monitoring system in the control room

View of the slugcatcher from the control room

Flare gas meter

Screen showing meter readings

Panels with buttons

Engineer (in SPIE overall) explaining to IET members. SPIE is a French company, like Total, and is hired by Total in HSE.

Group photo with the plant (photo taken by Total HR staff member). I am the smallest person in the picture.

Chambers containing different chemicals and gases

Plug panel

More pipes

Water pipes

Explosion-proof CO2 analyzer

Warning signs

Emergency shower station where water flow is triggered by placing your foot on the hinge below.

Slugcatcher

Photo of souvenier presentation by one of IET's former chairmen, Hj Sapawi and IET's IPRA, Sam Lee, to Total's Process Engineer, Tan and Supervisor in HSE, Roch.

A proudly displayed "10 years Without Loss Time Injury" plaque

A group photo just before departing from the plant

1 comment:

IET members visit TOTAL Onshore Processing Plant

The Brunei Times - link

Enhancing knowledge: The fifteen members from the Institution of Engineering and Technology (IET) Brunei Network posing outside the TOTAL E&P BORNEO BV (TEPB) Onshore Processing Plant (OPP) in Lumut during their visit, recently. Picture: Courtesy of TEPB

BANDAR SERI BEGAWAN

Wednesday, September 16, 2009

FIFTEEN members from the Institution of Engineering and Technology (IET) Brunei Network visited the TOTAL E&P BORNEO BV (TEPB) Onshore Processing Plant (OPP) in Lumut, recently.

The main purpose of the visit is to enhance their understanding towards the technology and technical practices in the local oil and gas industry.

It also serves as a platform for exchange in technical knowledge within the members and TEPB.

IET Brunei Network is a learned institution, affiliated with IET UK. It was inaugurated in 1997 in Brunei and also actively provides technical services consultancies to the various industry through its professional members working in diverse companies and organisations, and government departments.

The visit started with the recital of Surah Al-Fatihah, followed by an HSE briefing by the plant's HSE Supervisor, Roch Lee. It was then followed by the company profile presentation by TEPB Process Engineer, Tan Yah Tak. The visit continued with a tour around the plant aided with technical explanations by Tan. The visit concluded with a discussion and a Q&A session.

William Voon, highlighted that the plant's housekeeping is exemplary in the industry and congratulated the host team for keeping the plant in its present condition. Terry D Jayasuriya, who coordinated the visit noted that the discussion that followed the site visit was fruitful and provided a healthy platform for exchange of ideas, maintenance practices, and engineering standards.

Additionally, Koh Thian Chan also shared on the forthcoming 2nd International Conference of Institution of Engineering and Technology (IET) in June 2010. Updated details can be found at

www.theiet.org.bn.

The Onshore Processing Plant processes well fluid received from the Maharajalela offshore platforms located about 50km off the coast of Brunei into the South China Sea. Globally, TOTAL is one of the world's largest integrated oil and gas company comprised of 96,400 employees worldwide. It operates in over 130 countries including all lines of businesses.

In Brunei Darussalam, TOTAL is represented by TOTAL E&P BORNEO BV (TEPB) and TOTAL E&P

DEEP OFFSHORE BORNEO BV (TEPB-DO). Today TEPB employs approximately 120 local and expatriate personnel (25 expatriates, 38 Bruneian full-time local employees and 65 local contractors).

The various backgrounds and rich diversity of TEPB's personnel provide ample opportunity for beneficial exchange of experience and knowledge.

Post a Comment